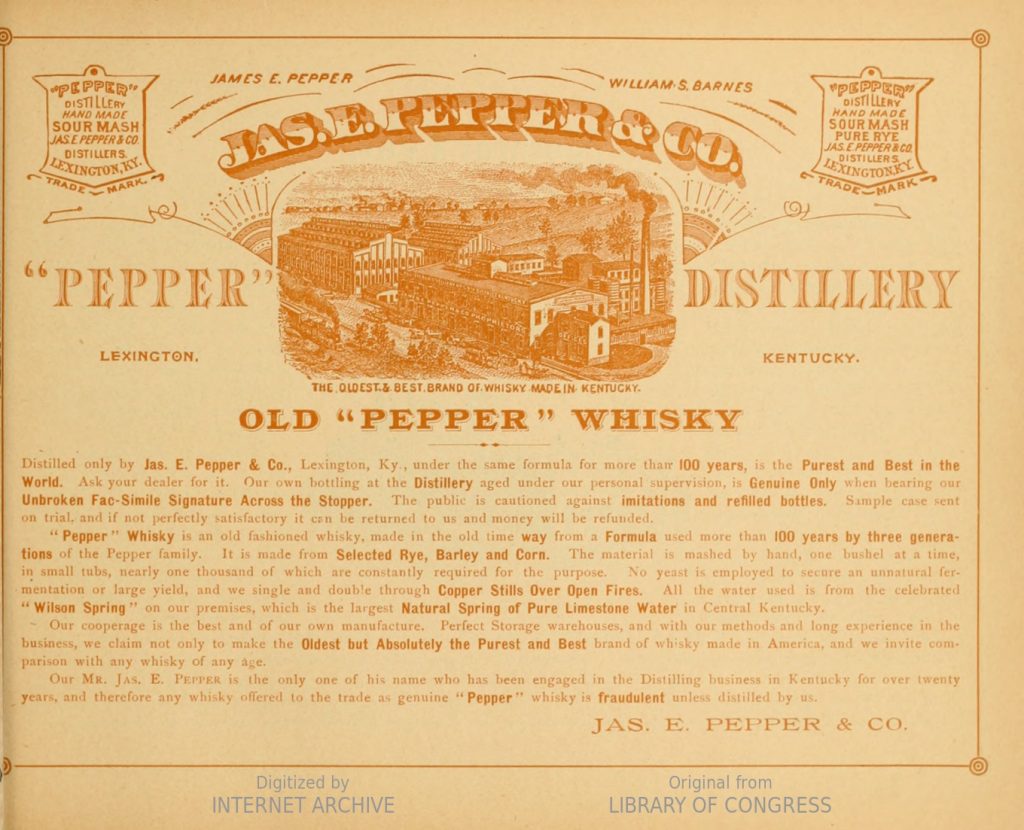

The above advertisement, from the 1889 Souvenir Programme of the Louisville Fall Celebration, shows the distillery then owned by James E. Pepper and William Barnes. E.H. Taylor bought out James Pepper’s family distillery in 1877, the original site of which is now Woodford Reserve Distillery in Versailles, KY. Pepper was able later to re-enter the business. He no longer had rights to the Old Crow name, which Taylor acquired in the 1860s, but produced fine whiskey again on the site of the former Henry Clay distillery in Lexington, KY.

The Pepper bourbon legacy was certainly indebted to James Crow who did his ground-breaking work there in the 1840s. We have seen how in 1884 Bonfort’s Wine and Spirits Journal linked both Crow and Oscar Pepper to a small tub mashing and fermentation system. It relied on backset to set the mash with no added yeast. This produced by my calculation a fairly low-yielding distiller’s beer, about 4.5% abv, due to the relatively uncontrolled methods used. But the claim was, it made for a better taste once the longer maturation period needed was achieved.

When James Pepper started distilling again he made whiskey mashed and fermented in the style his family and Crow had. This is evident from the above advertisement which stresses to the public, “no yeast is employed to secure an unnatural fermentation or large yield”. And it adds that 1000 small tubs are used to mash, by hand. This means no mash yeast or back-yeast – barm selected from the last ferment – was added. Mother Nature did all the work.

This use of natural fermentation, one which recalls the rare, surviving production of lambic beer in Belgium, connects James Pepper to Oscar Pepper’s and James Crow’s use of the same technique. James just continued it, as had E.H. Taylor when he owned the Pepper distillery and for whiskey made at his other plants including OFC, which is now Buffalo Trace Distillery in Frankfort, KY.

The 1889 Programme is a kind of industrial and mercantile survey. It has an interesting chapter, “Kentucky Whiskies”, which repays close reading, see especially pp 51-54. Sour mash is referred to but no claim is made that any Pepper, or James Crow, devised it. The reason for this in my view is the writer knew that the technique predated Crow’s arrival at Oscar Pepper’s plant c. 1840. Sour mash is not ascribed in the article to any one figure, but rather is said to have emerged for “convenience and economy”. When and how, was not known to the author. But it is interesting that the Programme states the first bourbon whiskey made in the state was a sweet mash whiskey with added yeast – I referred earlier to Edgar Preyer’s 1901 book which said the same thing.

The modern bourbon historian Henry Crowgey has discussed two recipes from the 1820s, one entails sweet mash in the sense of yeast being added, the other is evidently an alternating sweet and sour mash system where you start with yeast, then backset alone is relied on for a few runs, then a sweet mash is started up to ensure the backset doesn’t get too harsh and “fiery”. In both these recipes backset is used to scald the mash, as today, but clearly a lot of sweet mash production was mashed just with water (per my earlier discussions). Crowgey’s account is here. Other recipes for sweet mash and sour mash have been uncovered dating back to the same period. So sour mash was not new, but I apprehend Crow applied it methodically in an early industrial setting for “convenience and economy”.

The 1889 Programme does ascribe an honour to Crow: “doubling” “on wood” by steam. Doubling is the second stage of distillation, to refine the product and raise the proof. I read this to refer to a wooden doubler, or small pot still, which was heated by steam, not on a wood fire. Whether Crow actually did this is hard to say. I incline to think he did because the account is quite detailed. It explains that Crow’s whiskey was very good, was carried west in Kentucky from Frankfort by politicians who liked it – Frankfort is the state capital – and thus influenced distillers in the west. Nelson County, where much distilling occurs in Kentucky today, is proximate to Louisville for example.

Why would steam heat for a pot still be better than the old wood fire? Perhaps because the mash didn’t burn, a risk always present in fire-heated metal. In any case, the reference in the 1889 Programme is clearly to the second or doubler still, not the first or wash still.

The Programme further states: “West of the Kentucky River [shown in the image above], the distillers, with very rare exception, copied after Crow, used the sour mash hand-made method, and doubled in wood”. Note the reference to sour mash, these other distillers, who “copied” Crow, were all sour-mashing. Obviously then, Crow did too as we know from Bonfort’s account in 1884.

Numerous improvements in bourbon manufacture have been ascribed to Crow, but I think it is reasonable at least to read both accounts as meaning that Crow sour-mashed with backset and no added yeast, and used a wood doubler heated with steam to bring his distillate to final proof. One always wishes for more information than there is, but we need to work with the information we have. These two sources, carefully examined, provide some very good information on James Crow’s role in bourbon history. Of course, he may have done more, methodical aging has often been mentioned, for example. Indeed his whiskey was noted for being red, it was called the “red cretur” – in effect the aged red/brown bourbon we have today vs. the white or very pale whiskey still common before the Civil War.

The innovation Bonfort’s ascribed in 1884 is undoubtedly true in my opinion. It was recorded, not just in a popular publication, but a specialist one, devoted to the distilling industry. And Bonfort’s mentioned not just Crow, but Oscar Pepper whose son was still living and active and a highly respected figure in Kentucky distilling. I don’t think Bonfort’s would misstate information with historical overtones under these circumstances.

Finally, the ad above confirms the account because it advertises prominently the same method used five years later by the son.

However, James Pepper’s ad also states, “we single and double through Copper Stills over open fires”. No reference to a wood doubler operated by steam! If James Pepper was following Crow’s method, why would he not use the wooden steam doubler Crow apparently did? This is hard to say. Maybe he didn’t stick with that part, certainly the industry had pretty much dispensed with wood for this purpose by the end of the 1800s. Gerald Carson’s bourbon history (1963) states that E.H. Taylor discarded the “uncleanly” wood still, so it makes sense James, who had had many dealings with Taylor, did too. In fact, James made Old Crow whiskey for Taylor after the brand name transferred over as mentioned above…

Certainly today all alcohol stills, of whatever type, are made of metal except for a wood column still and wood pot still, both 1800s vintage and still operating to make rum at El Dorado in Guyana. Peruse its website and look at them yourself. The column still is a frame of wood filled with packing or perforated plates. Steam shoots up through the column to vaporize the alcohol from the descending wash. The pot still is also a wood frame which holds a metal pot in which the wash is boiled.

Wood may have caused problems to an industry increasingly concerned with sanitation and probably was more costly to maintain than metal. So that part had to go, one infers.

The Mother Nature yeasting part did too, finally, by c. 1910.

What stayed? Backset to acidify the mash. All bourbon distilleries today use it. They could add a lactic acid culture and dispense with the backset, but it may contribute some flavour and perhaps also bacteria which create esters and/or more alcohol. And just perhaps, they do it because it is a way to hang on to some old tradition. Bourbon is nothing if it ain’t that. Why, travel down to Kentucky and visit the plants, chat with the people, see for yourself. It’s pretty country too, as you see in the image above.

Note re images above: The first is from the 1889 Programme linked in the first paragraph. The second, of Frankfort, KY and area, is from Wikipedia, here. Both are in the public domain and believed available for educational and historical use. All feedback welcomed. In addition, all trademarks shown belong to their owners or duly authorized users.